When I first unpacked a delicate electronic component that had traveled halfway across the world and found it in perfect condition, I couldn’t help but appreciate the silent hero inside the box — the foam. 📦 It wasn’t just any foam; it was an engineered material that absorbed impact, resisted vibration, and protected valuable goods from the harsh realities of transport. That’s when I learned about Durfoam, a brand redefining packaging technology through innovative foam solutions designed for shock and impact protection during transit. 🌍

Shipping and logistics have evolved dramatically, but one thing remains constant — the need to protect goods efficiently. Every bump on the road, every vibration in the cargo hold, and every drop on a conveyor belt can cause serious damage. Durfoam tackles this challenge with its advanced packaging foams, built using polyethylene foam, a lightweight yet resilient material that combines flexibility and strength. 💪

Unlike traditional packaging fillers like bubble wrap or polystyrene, Durfoam’s engineered foams are designed scientifically to absorb and disperse kinetic energy. When a product encounters a shock or fall, the foam compresses momentarily and then regains its shape — preventing the impact from transferring to the product itself. This elasticity ensures reliable protection even after multiple hits, making it perfect for repeated use in industrial and export packaging. 🚚

The secret lies in cross-linking technology. Through physical and chemical cross-linking, Durfoam enhances the foam’s molecular structure, increasing its tensile strength and impact resistance. Both physically cross linked polyethylene foam and chemically cross linked polyethylene foam are used across different packaging applications — from cushioning delicate medical instruments to securing large automotive components. 🔧

Here’s a quick comparison table showing how Durfoam’s cross-linked foams outperform traditional packaging materials in shock and impact protection:

| Packaging Material | Impact Absorption | Reusability | Moisture Resistance | Durability |

|---|---|---|---|---|

| Bubble Wrap | Low | No | Low | Low |

| Polystyrene Foam | Medium | Low | Medium | Moderate |

| Durfoam Cross-Linked PE Foam | High 🚀 | Yes | Excellent 💧 | Superior |

In practice, this means fewer damaged goods, fewer returns, and a cleaner supply chain. Many global manufacturers rely on pe foam packaging from Durfoam because it offers the best balance between protection and sustainability. Unlike single-use plastics, these foams are recyclable and reusable, aligning with modern environmental standards. 🌱

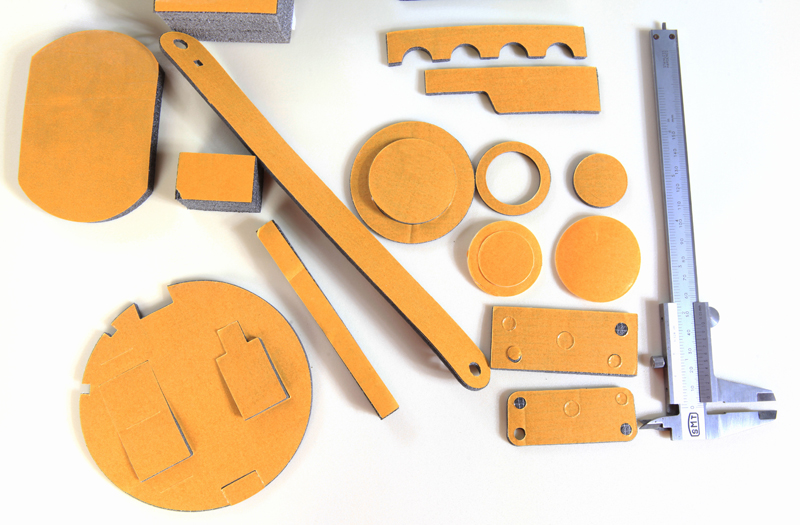

I recently visited a warehouse using Durfoam inserts for high-value electronics. Workers showed me how the foam’s custom-cut designs perfectly cradled each item, keeping it stable even during vibration tests. After multiple drop trials, not a single device showed damage — a clear testament to the precision and resilience of Durfoam’s materials. 🎯

Another underrated feature is moisture and chemical resistance. Many traditional packaging foams absorb humidity, leading to mold or corrosion during long shipments. But Durfoam’s closed-cell structure keeps moisture out completely, ensuring both safety and longevity. This makes it a trusted choice not just for consumer goods, but also for sensitive components like medical devices and electronics. 💉💻

And it’s not just about protection — aesthetics matter too. Because Durfoam’s materials can be molded, laminated, or printed, they add a professional finish to packaging, helping brands elevate the unboxing experience. It’s the perfect blend of function and presentation. 🎁

Here’s where this cutting-edge technology is born 👇

In conclusion, as global logistics demand smarter, safer, and more sustainable packaging, Durfoam continues to lead the charge. By combining material science with environmental responsibility, its foam solutions deliver the perfect balance of shock absorption, moisture control, and reusability — ensuring that every product arrives exactly as it left: flawless. 🌍✨

You should also read these…

- surgeblog.com – understanding fat composition choosing the right o

- huesly.com – steam vac ban errors and wrong ban appeals

- huesly.com – from prototype to production streamlining product

- olddry.com – app and technical problems and solving methods on

- sixrep.com – missing mentions on twitterx filters muted words a

- axtly.com – quick one pan chicken dinners for one

- axtly.com – kid friendly camping tips for first time parents

- beofme.com – the ultimate wheel of names trick you need to try

- noepic.com – beginner guide to creating short tiktok sketches

- toojet.com – twitter x accessibility settings not working contr